In a recent New York Times discussion, reporter Janet Morrissey calls recent digital dentistry advances “a technological metamorphosis” taking place within the dental industry.

“Among the latest innovations: The use of digital scanners and 3-D printers to offer same-day crown replacements, smart toothbrushes that talk back to you via a phone app when you’ve missed an area while brushing, lasers that eliminate the need for an anesthetic, and digital tools that detect oral cancer.

Some of these advances had been around for a number of years but had not been widely adopted because of high equipment costs, lack of training or dentists who were more comfortable with older, traditional equipment.”

New York Times Contributor Janet Morrissey

An explosion of advancement is occurring and dentists today navigate a seemingly endless array of options swirling around them.

How can CAD/CAM dentistry benefit a patient—and a dental practice?

Computer-aided design (CAD) and computer-aided manufacturing (CAM) enhance the design and creation of dental restorations such as crowns, veneers, inlays, onlays and bridges from a single block of ceramic.

Time is a precious commodity, and with an entire chairside process that can be completed within a range from 40 minutes to 2.5 hours, CAD/CAM is an obvious answer.

With a conventional restoration, a temporary is placed inside a patient’s mouth for one to several weeks while the lab produces the restoration. After waiting one to several weeks, the patient returns to the office to have the temporary removed and the restoration bonded in place.

CAD/CAM dentistry, or Chairside CAD/CAM, enables a clinician to design and create a restoration in less than an hour and bond it on the same day.

It all begins with a wand.

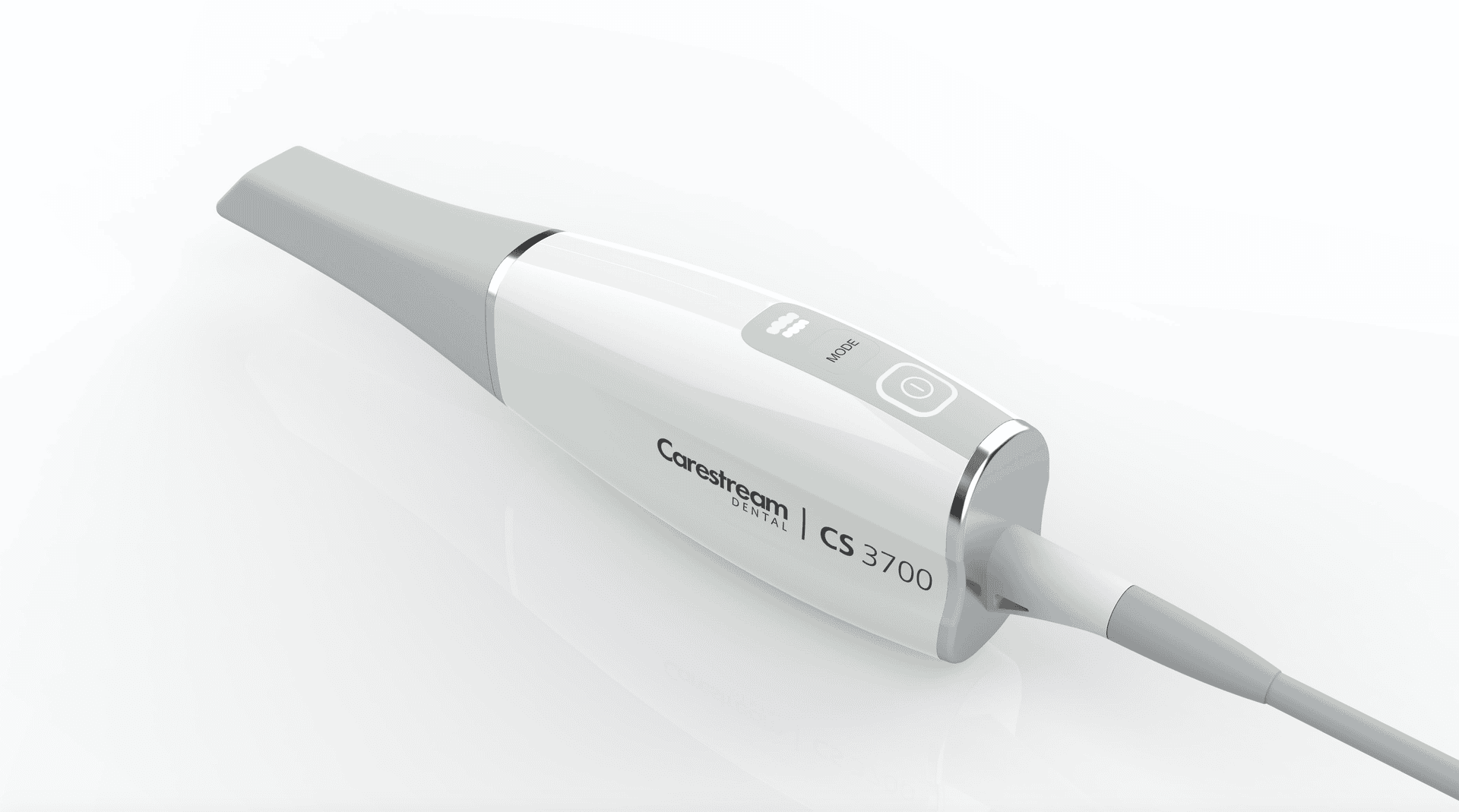

It takes approximately a minute-and-a-half to capture a digital impression of prepared teeth. An impression of the teeth in the opposite arch takes just 45 seconds.

What drives the process? An intraoral scanner is used to capture a direct optical impression. The scanner projects a light source onto the area to be scanned. The images are captured by imaging sensors and are processed by scanning software, which then produces a 3D surface model.

Shown above, is one example from Carestream Dental: the CS 3700.

Find out how to choose the best scanner for a dental practice.

Next: Design and Produce

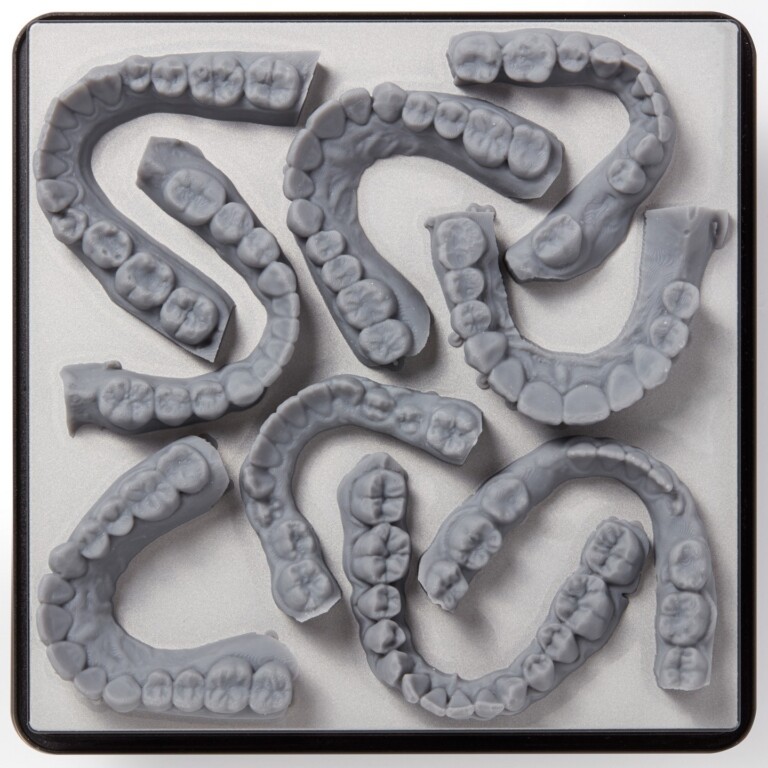

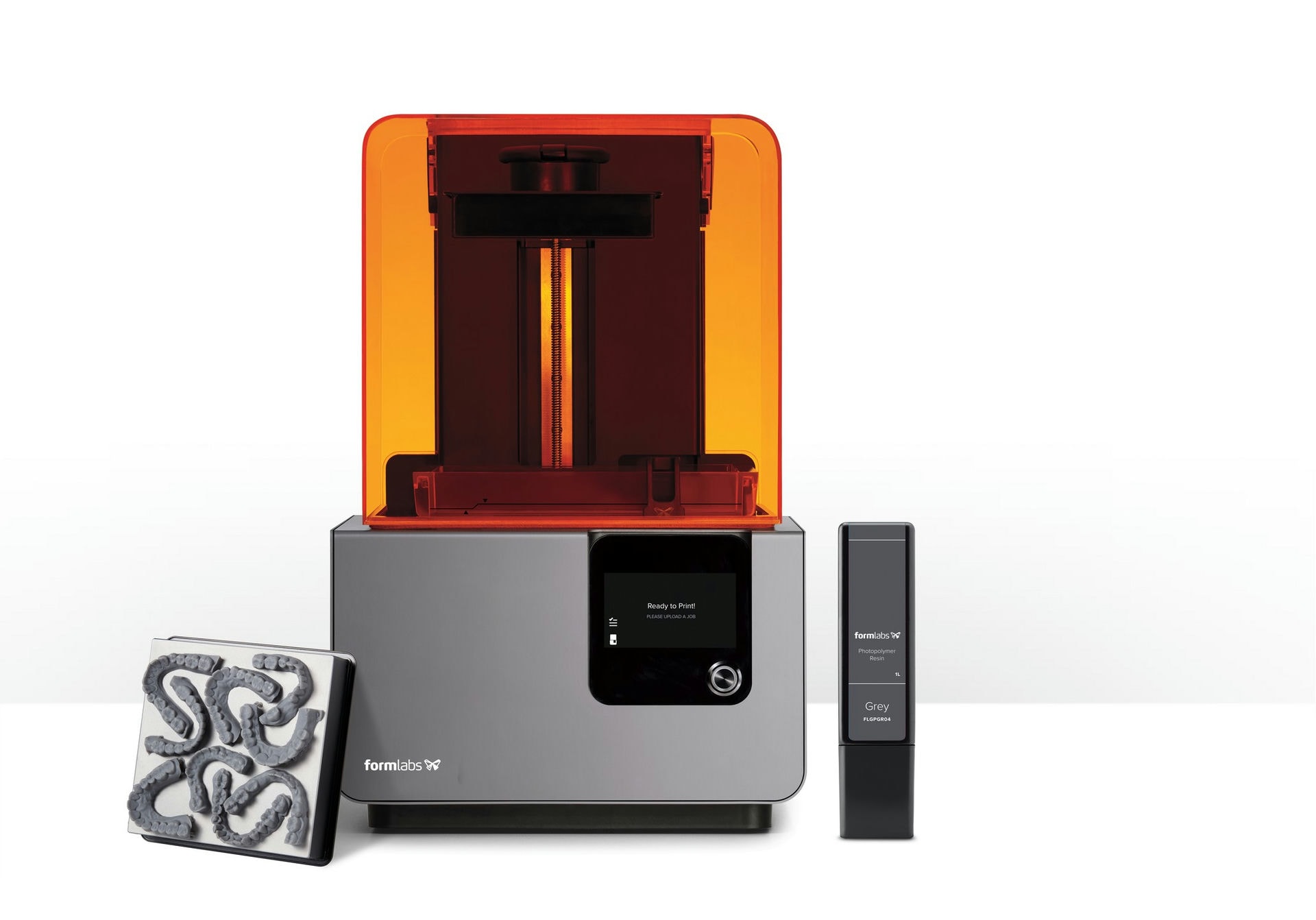

Once a digital image is captured, a crown is virtually designed and directed to a dentist’s in-office milling machine or 3D printer. The results are shown at top and above.

According to Formlabs:

“3D printing or additive manufacturing (AM) technologies create three-dimensional parts from computer-aided design (CAD) models by successively adding material layer by layer until physical part is created.

While 3D printing technologies have been around since the 1980s, recent advances in machinery, materials, and software have made 3D printing accessible to a wider range of businesses, enabling more and more companies to use tools previously limited to a few high-tech industries.”

How much do they cost and how to choose the best one for a dental practice? Learn more here.

Ready for more digital dentistry advances?

- Read the full article by reporter Janet Morrissey in the New York Times.

- Gain insight on costs, comparisons and product test drives of the latest digital dentistry tools at Benco’s website.