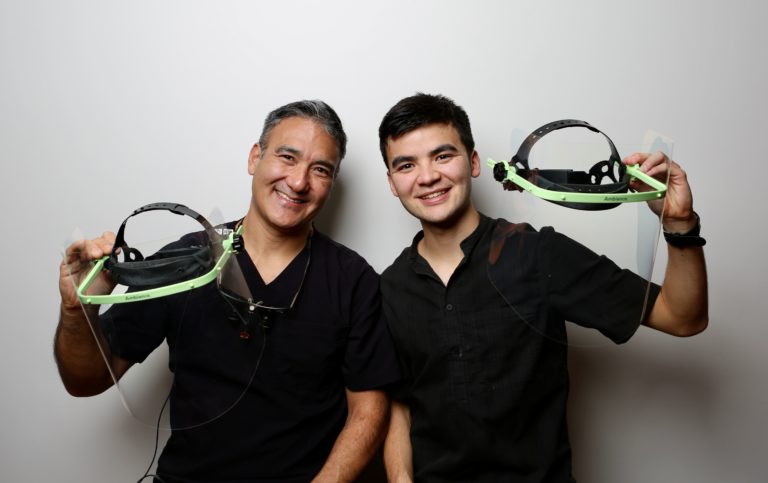

When the world of oral care was profoundly impacted by the pandemic, a father-son duo of a dentist and Dyson engineer from Vancouver, Canada combined talents to improve the dental experience. Faced with the challenge of protecting himself while returning to the dental practice, Dr. Scott B. Yamaoka, DDS, MS, FRCD(C), 57, with the help of his son, Dyson engineer Zach Yamaoka, 23, created the Ambience Shield. This innovative product provides greater clarity for the dental team, while improving loupe fit and protecting against splatter that occurs during dental treatment.

How did Dr. Scott B. Yamaoka, DDS, MS, FRCD(C) come up with the idea for the Ambience Shield?

Dr. Yamaoka’s interest in dentistry began early, sharpening instruments in his father’s dental office. Taking lessons learned from his father, Dr. Yamaoka strived to help people while maintaining a good life balance. When the COVID-19 pandemic occurred, keeping his staff and patients safe took top priority. Returning to the dental office, it became clear that the current personal protective equipment (PPE) was insufficient. He felt the face shields were blurry and ill-fitting, but necessary to avoid splatter and droplets.

“I had the idea because I understood the need, so I made the first version in our home garage using a modified construction hard-hat and school projector plastic. I started giving them away to fellow dentists, and the response was fantastic. I knew that my rough and ready version could be improved and taken much further, but I didn’t have the manufacturing or design experience to make it happen.”

Dr. Scott B. Yamaoka, DDS, MS, FRCD(C), explaining his idea for the Ambience Shield for dentistry

How did Dr. Scott B. Yamaoka’s son, Zach, get involved in the Ambience Shield project for dentistry?

To create a more refined design on a larger scale, Dr. Yamaoka reached out to his son, Zach, who was working as a Dyson engineer at the time. As a child, Zach enjoyed visiting his dad’s office, doing dental volunteer work, and seeing the first-hand impact that oral care had on people’s health and self-esteem. However, he was more interested in physical product development.

“After graduating from school in the UK, I was offered a position to work in Dyson’s secret lab. It was a dream opportunity. Dyson is by far the best consumer product company in the UK and one of the top in the world. I was learning a lot and working really hard. Then the COVID pandemic happened.”

Zach Yamaoka, co-creator of Ambience Shield, on his tenure as a Dyson engineer

“My dad and I would speak frequently about what was going on in the world. During those conversations, I would hear about his frustrations working with shields. He told me about the first prototype that he had made, what was working well and what could still be improved. I was intrigued to see if I could solve his problems and help out the dental community,” Zach Yamaoka explained in an interview.

Father-son duo of a dentist and Dyson engineer began the process of manufacturing the Ambience Shield for dentistry

The project was far from an easy venture. While the design was created just two weeks after the father-son duo began working together, it took time to receive the proper PPE certifications and finalize the packaging design. When asked about the design of the product, Zach attributed much of the success to the 15 clinicians the duo worked with through the 58 prototype models of the shield.

“Using a 3D printer made this rapid development possible. It’s an awesome technology that dentists are becoming familiar with as well.”

Engineer Zach Yamaoka, co-creator of Ambience Shield

Father and son credit each other in the design process. Both the clinical experience of Dr. Yamaoka and the design expertise of Zach Yamaoka were essential in creating the Ambience Shield, which is available through Benco Dental. They aim to continue their partnership to help dentists achieve higher rates of success when placing dental implants in the future.

Learn more about their story: